Services at a Glance

Our spacious warehouse allows us and our customers to have quick access to general structural steels and fine-grain structural steels, as well as wear-resistant steels.

We can offer our customers precisely the sheet metal grades they need. Upon request, we provide the corresponding factory certificates for these materials.

A re-stamping authorization from TÜV-Nord is available.

Even if you have very specific requirements, don’t hesitate to call us.

General Sheet

Metal Data

- Sheet thicknesses from 3-500mm

- Sheet widths from 1000-3500mm

- Sheet lengths of up to 16000mm

- Individual piece weights of up to 50 tons

Standard Sheet

Metal Grades

- 1a Heavy Plates as well as Slabs and Oversized Sheets

- S 235 (EN 10025)

- S 355 (EN 10025)

- P 355 / P 460 (EN 10028)

- S 690 (EN 10137)

- HB 400 / 450 /500

Special

Samples

- Fracture contraction according to EN 10164 tensile test Z 15; Z25; Z35

- Weld bend test according to SEP 1390

- US-testing according to SEL072/EN 10160

- Additional subsequent inspections by GL/TÜV or other classification societies possible

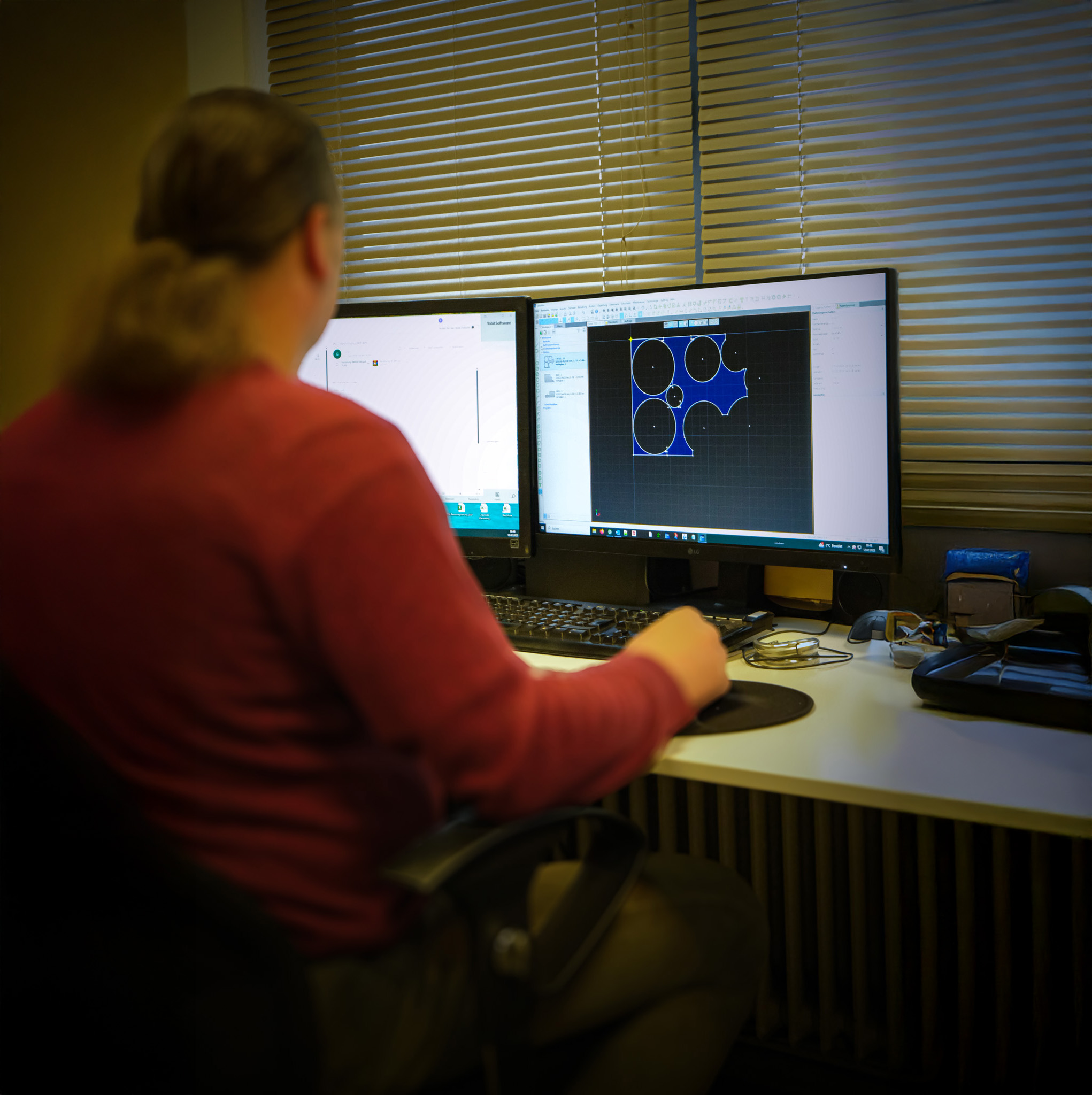

Flame Plasma and Laser Cutting

One of our core competencies is the production of custom sheets, individually tailored to customer requirements. Two modern CNC flame-cutting machines with up to six torches process steel sheets with thicknesses of up to 500mm on a cutting table measuring 6.5 meters in width and 26 meters in length.

Our Messer plasma cutting system features a table 5.6 meters wide and 14 meters long. All sheets up to a thickness of 25mm are processed here. This system includes a fixed head and an additional beveling head, making it ideal for clean weld seam preparation.

Welding

We are a certified welding company with manufacturer qualifications for welding in accordance with DIN EN1090

The following welding processes are used in our company: Metal Active Gas Welding (MAG), Metal Inert Gas Welding (MIG), and Tungsten Inert Gas Welding (TIG).

Steel Grit Blasting

To ensure that components – whether raw materials or finished workpieces – can be optimally processed further, they usually need to be clean, meaning free of scale, rust, or other contaminants. Blasting is a reliable, economical, and environmentally friendly processing method for this purpose. Using steel grit as blasting material, we achieve perfectly cleaned surfaces – the prerequisite for a well-adhering, corrosion-resistant, and visually appealing coating. Our system is suitable for blasting sheets, pipes, and profiles. It features a pass-through opening of 2,600 mm in width and 650 mm in height.

Processing

To prepare and finish the flame-cut parts we produce according to customer requirements, we offer a wide range of services related to steel sheets: welding, beveling, bending, pressing, rolling, straightening, mechanical processing, heat treatment, and corrosion protection.